Cotton Waste

Cotton Waste Products

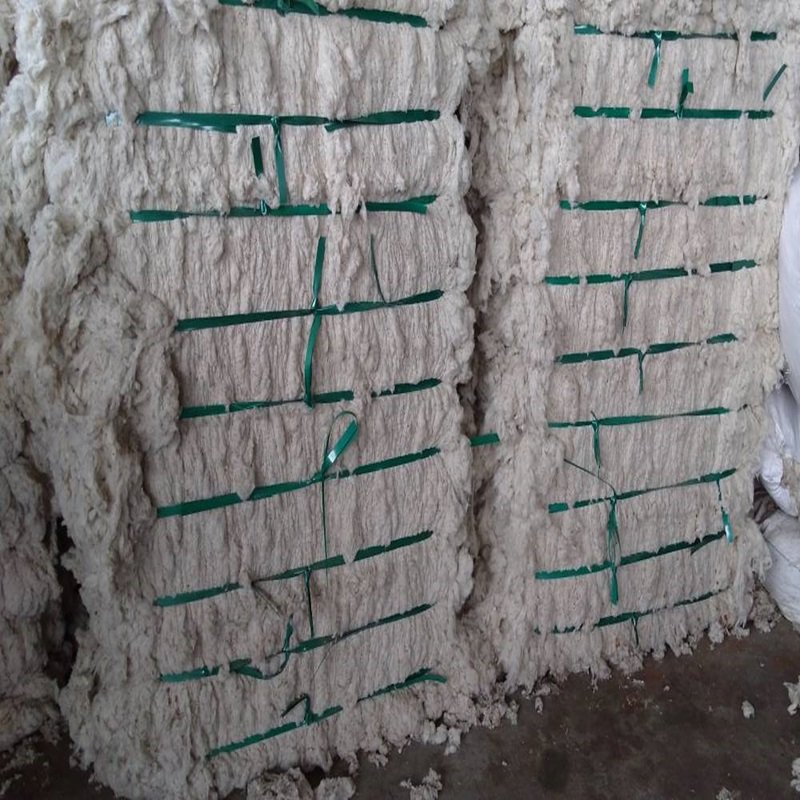

Cotton Waste

Cotton waste refers to the by-products generated during the processing of cotton and textile manufacturing. This waste includes various forms such as comber noil, carding waste, lint, and hard waste. While cotton waste is often seen as a by-product, it has numerous applications, including recycling into lower-grade yarns, production of non-woven fabrics, and industrial uses like cleaning cloths and automotive materials. Due to its biodegradable nature, cotton waste can also be used in composting and even paper production, making it an important resource in sustainable practices within the textile industry.

Types of Cotton Waste Products

100% Cotton Comber Noil

100% Cotton Comber Noil is a by-product of the cotton combing process, primarily composed of short fibers removed to enhance the quality of the main cotton yarn. These short fibers, known as comber noil, are typically 10-25 mm in length and are considered to be of lower quality compared to the longer fibers used in high-quality yarn production. It is commonly used in the production of absorbent cotton (such as for medical and hygiene products), recycled cotton yarn, and non-woven fabrics. It can also be blended with other fibers to produce coarse yarns for products like mops, rugs, and low-cost textiles. Additionally, Cotton Comber Noil is often used in paper production, especially for high-quality and specialty papers.

Cotton Yarn Waste

Cotton yarn waste consists of remnants and by-products generated during textile production, including leftover yarns, broken threads, and production excesses. This waste is categorized into soft waste, such as unused yarn, and hard waste, which results from production errors. Despite its origins, cotton yarn waste has valuable applications. It can be recycled into new, lower-grade yarns for use in products like carpets and cleaning cloths, or processed into non-woven fabrics for insulation and packaging. Additionally, it can be utilized in eco-friendly products, reducing the environmental impact of textile manufacturing. Cotton yarn waste can also be composted, contributing to sustainable practices in the industry.

Cotton Yarn Hard Waste

Cotton yarn Hard waste refers to the remnants and by-products generated during the manual handling of cotton yarn in textile manufacturing. This waste includes short yarn pieces, broken strands, and loose fibers that are often discarded during processes like spinning and weaving. Despite its lower quality, cotton yarn Hard waste has several valuable applications. It can be recycled into lower-grade yarns for use in products like cleaning cloths and industrial rags, or processed into non-woven fabrics for insulation and packaging. Additionally, being biodegradable, it can be composted or used in specialty paper production. Utilizing cotton yarn Hard waste helps reduce textile industry waste, promotes sustainability, and minimizes environmental impact.

Cotton Waste pnemafil

Cotton Waste Pnemafil refers to a specialized form of cotton waste utilized in pneumatic and filtration applications. This type of cotton waste consists of short fibers and remnants from cotton processing, which are processed to enhance their effectiveness in filtering air or liquids. In filtration systems, Cotton Waste Pnemafil provides efficient particle capture, trapping dust and impurities due to its fibrous nature. It is also used in pneumatic systems to filter air or materials, ensuring clean and contaminant-free conveyance. By repurposing cotton waste for these applications, industries can reduce waste and support more sustainable practices while improving their filtration and pneumatic systems' efficiency.

Cotton Waste Roving

Waste roving consists of the by-products generated during the roving stage in yarn manufacturing, where fibers are drawn out and twisted into strands before spinning into yarn. This waste includes short fibers and irregularly twisted strands that are not suitable for high-quality yarn production. Despite its lower quality, waste roving can be effectively repurposed. It is often recycled into lower-grade yarns or blended with other fibers for new textiles. Additionally, waste roving is utilized in the production of non-woven fabrics, such as insulation and padding, and can serve as a filler material in various applications. By recycling and repurposing waste roving, industries can minimize waste and support more sustainable manufacturing practices.

Cotton Waste Flat Strips

Cotton Waste Flat Strips are remnants of cotton material cut into flat, strip-like shapes during textile processing. These strips, which can vary in width and length, are often produced from fabric or yarn remnants during trimming or cutting. Despite their lower quality, cotton waste flat strips have valuable uses. They can be recycled into new textile products, such as braided rugs and mats, or used in industrial applications like padding and insulation. Additionally, they are popular in craft projects for making woven items and decorative pieces. By repurposing cotton waste flat strips, industries and artisans can reduce waste and support more sustainable practices.

Cotton Waste Carding

Cotton Waste Carding refers to the by-products produced during the carding process in cotton processing, where fibers are cleaned, disentangled, and aligned for spinning. This waste includes short fibers, neps (tangled fiber clusters), and impurities removed during the carding. Despite its lower quality, cotton waste carding has valuable applications. It can be recycled into lower-grade yarns or blended with other fibers to produce new textiles. Additionally, it can be used in non-woven fabrics for insulation and padding, or as filler material in various products. Given its biodegradable nature, carding waste can also be composted to enhance soil health. Utilizing cotton waste carding helps reduce textile waste and promotes more sustainable manufacturing practices.

Cotton Waste Lickerin

Cotton Waste Lickerin refers to the by-products generated during the lickerin stage of cotton processing, where a rotating cylinder removes debris, seeds, and small impurities from cotton fibers. This waste includes short fibers, seeds, dirt, and other contaminants separated during the process. Although lower in quality, cotton waste lickerin has several valuable applications. It can be recycled into lower-grade yarns or blended with other fibers for new textiles, used in non-woven fabrics for insulation and padding, or employed as filler material in various industrial applications. Additionally, being biodegradable, it can be composted to enhance soil health. Utilizing cotton waste lickerin helps reduce textile waste and supports more sustainable manufacturing practices.

Cotton Waste Dropping

Cotton Waste Dropping refers to the by-products collected during the cotton spinning process, consisting of small pieces of cotton fibers that fall off or are discarded due to imperfections or short lengths. This waste, often lower in quality due to its short fibers and imperfections, has several practical uses. It can be recycled into lower-grade yarns or blended with other fibers to produce new textiles. Additionally, it is used in non-woven products like insulation materials and cleaning cloths, or as filler material in industrial applications. Being biodegradable, cotton waste dropping can also be composted to enhance soil quality. Repurposing this waste helps reduce textile industry waste and supports sustainable practices.

.png)